Collinson… let’s build something great together.

A trusted partner

As well as our long serving in-house team, we have been the sole UK & Ireland partner for Best-Hall from Finland since 2003. Best-Hall were founded in 1975 and to date have designed & manufactured more than 5,500 steel frame fabric buildings.

You are therefore assured of having both Collinson and Best-Hall to rely upon to deliver a premium product and service and the advantage of having two long standing companies to ensure your building will be supported in the long term.

Proven Design & Engineering

Our structural and tensile fabric design principles are proven with nearly 50 years experience in the design & manufacture of tensile membrane buildings. In the UK & Ireland we have buildings in use as far north as Shetland & Stornoway which demonstrates the world class engineering that are as standard built-in with every Best-Hall/Collinson building project.

Not all Fabrics are made equal

The specification and engineering of the tensile membrane covering the building superstructure is one of the key aspects when choosing a tensile fabric building.

All our buildings utilise the Serge Ferrari range of membranes which are known globally as the market leading producer of architectural membranes. The longevity and performance attributes of the Serge Ferrari membrane combined with our Design Engineering ensure our tensile membrane coverings will perform for decades to come.

A lasting relationship

For us, the relationship doesn’t end the moment we’re off site. We place huge importance on after care and creating lasting relationships with our customers, who often come back to us for their next project.

A family firm with strong values

Collinson is a family owned business founded in 1962 however during 2003 we were approached by Best-Hall Oy from Finland to create a Construction division to represent them in the UK & Ireland. Collinson Construction remains family owned and operated. Best-Hall remain privately owned and are part of the Wiklof Group which will ensure your building will be supported for many decades to come.

We have built a team with deep knowledge and experience of the tensile industry.

From design through to completion and aftercare, our priority is providing clients with an excellent service, a transparent relationship, and a high-quality project.

Technical Specification

Tensile Membrane

- The steel frame is covered using Serge Ferrari membranes which are recognised globally as the market leaders in architectural membranes.

- This ensures longevity in performance and visual appearance.

- Patented Precontraint technology places the base textile under bi-directional tension during the complete manufacturing process.

- Proven longevity: the thicker coating provides greater protection to the base textile and greater mechanical resistance characteristics.

- Anti-Wicking: conventional covers allow water capillarity whereas Serge Ferrari technology prevent this action which will harm the membranes performance and appearance over time.

- Limited Creep: Precontraint tech ensures significant reduction in the creep phenomenon which is 3 to 4 times higher for conventional fabric membranes.

- In reality this means our membrane cover will not stretch and will remain drum tight over its life compared to other membranes.

- This enhances the life span and reduces risk of wear & tear.

- Tensioning system: The BestHall tensioning system has been proven over many decades of use and development to ensure the membrane remains fully in tension throughout its life and does not require re-tensioning or adjustment throughout its lifespan unlike other solutions.

Steel Frame

- We use only European SSAB and Tata Steel to ensure the highest possible quality as European standards ensure a stronger steel is produced, which is essential for buildings.

- For a superior finish, our steel frames are powder coated at our in-house automated paint line. This provides a smooth surface, minimising friction between the PVC cover and the frame, thereby reducing abrasive wear on the cover.

- The environmentally friendly and aesthetically appealing powder painting also gives the frame excellent corrosion protection even up to class C5, if needed.

- Every structure is individually designed and engineered based on the environmental, wind and snow loads of the buildings location, ensuring a robust and reliable building solution.

- As the market leader in quality, Best-Hall has received the European CE marking for its load-bearing structures. In accordance with the quality system, all materials are traceable, tested and equipped with a material certificate. Best-Hall’s designers also have the qualification of a designer of steel structures (AA) granted by FISE, which is the highest level possible in steel construction.

Specification

- Steelwork Treatment – Shot blasted Sa 2,5 and Powder Coated to meet the standard SFS-EN ISO 12944-2 C3/C4/C5 class of exposure.

- Colour: Light Grey or White

- Execution class EXC2 according to SFS-EN 1090-2.

- CE-marked steel frame.

- Consequence class CC2.

- Tensioning & Cross buckling CHS/SHS elements are manufactured from Magnelis®

- Structural Tolerances according to Eurocodes: L/300 and H/150

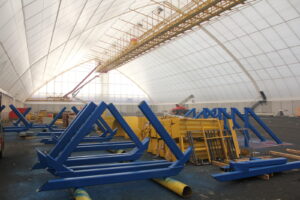

Special load case

In addition to the wind/snow loads we can also design the building to withstand additional loads from ancillary equipment such as conveyors or other heavy items as needed. Photo shows roof mounted conveyors supported by our steel frame (note building also has our optional inner liner system)